Excavator Demolition Grapples – Sjheavy

We Deliver Excellent Product

The ideal demolition grapple will satisfy your current and future job requirements. You wouldn’t want a piece of equipment that does a few jobs. We at Sjheavy can assist you in selecting a versatile and cost-effective sorting grapple.

From mini excavator & digger, hydraulic breaker, grapple, compactor, demolition crusher, hydraulic shear, up to other attachments, we have it all at Sjheavy.

Send us a message, and we will give you the product you deserve.

Demolition Needs A Strong Equipment

Grapples come in various styles, each with a specific use and application. Sjheavy demolition grapple has a powerful clamping force and high operational agility.

The sorting grapple is made of high-quality, impact-resistant steel designed for heavy use. And it is beneficial in places where sorting the materials must be handled quickly.

Features and Functions

- Fully integrated hydraulic rotator, which can bear the stronger force.

- Double control valve reduces shock on motor greatly

- Integrated motor base effectively protect gear and rotary support, prolonging its life

- Large volume cylinders greatly improve grab capacity

- Wear-resistant steel prolongs grabs’ lifetime.

Related Products

Excavator Log Grapple

Sjheavy log grapples are specially designed to securely clamp around any logs or large tree trunks and safely move them into a dump truck or a lorry. This allows you to safely carry away any debris or material from a construction or forestry site to a dumping site.

Orange Peel Grapple

With industry-leading technology, Sjheavy orange peel grapples are so tough and durable that the limits are being pushed. Because of their steel alloy bodies and abrasion-resistant tines, these orange peel grapples make your job easier than ever.

Excavator Rock Grab

The Sjheavy rock grab on the excavator can be used to shift large stones, rocks, and scrap. Due to its sharp tines and cutting edges on the front, the stone grab attachment can dig deep into the scrap in order to fully load the inner space of the grapple.

Sjheavy: The Right Equipment Provider for You

Sjheavy is a one-stop solution company where all types of grapples are all under one roof. We are the leading brand and a highly-respected equipment supplier in China.

We cooperate with renowned industrial suppliers to provide cost-effective equipment with a low failure rate to our end users.

Like how we want the best for ourselves, we also want to give our distributors, resellers, and end-users the best service and product.

We handpicked our materials so we could serve our clients with high-quality products all over the world.

With over ten years of experience, our R&D team can tailor your request to meet your requirements.

Sjheavy is the suitable equipment provider for you. Send us a message, and we will give you reliable and efficient products.

Gallery

Why Sjheavy Demolition Grapples

Sjheavy demolition grapples feature 360-degree rotation, rapid sorting, accurate load management, edge-to-edge contact, and zero-clearance products. It will help you operate easily while maneuvering heavy things on the field.

The Sjheavy demolition and sorting grapple can handle both primary and secondary demolition, intended for quick and efficient material handling. We designed our sorting grapple to meet your demolition and recycling needs.

For us, the quality and efficiency of our product are our top priority. We have a sub-contracted specialist company who manufactures our products. Still, our technical staff conducted all design, quality control, and inspection.

You won’t have to worry about your grapple buckling because we use high-quality materials to have a high-quality product.

We won’t be the leading equipment supplier if we’re not the best.

Sjheavy has received numerous certifications, including ISO 9001 and CE. So, we can assure you of the best products.

Demolition Grapple FAQ

Construction is a rewarding job, but it’s demolition work that is truly fun! It is hard to deny the feeling of satisfaction when you watch a building crumble to the ground. A demolition job, however, needs proper equipment. One vital machine that cannot be left out is the demolition grapple!

Demolition Grapple FAQ

Construction is a rewarding job, but it’s demolition work that is truly fun! It is hard to deny the feeling of satisfaction when you watch a building crumble to the ground. A demolition job, however, needs proper equipment. One vital machine that cannot be left out is the demolition grapple!

1. What Is A Demolition Grapple?

Demolition Grapple

A demolition grapple does precisely what its name implies and says. It grabs hold of debris and scraps, moving them out of the way. This heavy equipment deftly handles many materials — from insulation to rebar.

This grapple lifts rocks, timber, and other heavy items or materials for transportation purposes. It deals with handling demolition materials of different sizes and weights.

You can expect to find this kind of grapple in the construction and industrial sectors worldwide. A demolition grapple for excavators has a primary use of holding debris and moving them.

With the continuous rise in construction individual activity, there is also an increasing demand and need for demolition grapple equipment.

2. What Does A Demolition Grapple Look Like?

Look of demolition grapple

A demolition grapple is a universal tool for sorting, demolition, and loading various materials. The basic structure is quite simple and is similar for most brands. It has a rigid main body and two moving jaws — both are mounted on both frame ends.

Most demolition grapples have wide jaw openings. A jaw or claw that can sort scraps is called a ditch cleaning bucketsorting grapple. Most brands prioritize the ‘wide jaw opening’ feature since it determines how much it can lift without hassle.

See this video to witness how demolition grapples sort out waste: https://youtu.be/_dG-Q-9ZHU0

3. How Does A Demolition Grapple Work?

Demolition Grapple Work

The lower jaw on some grapples remains stationary and unmoving while the upper jaw operates the bucket cylinder. This version is simpler and less expensive. It also needs lower maintenance.

The more popular but higher-cost demolition grapple has claws that move simultaneously, and it is powered by 2-4 connected lines.

An operator sits on the cab inside the vehicle. They will manipulate the demolition grapple from there.

To see demolition grapple in full-demolition mode, here is a video: https://youtu.be/VdFmO3qzfXA

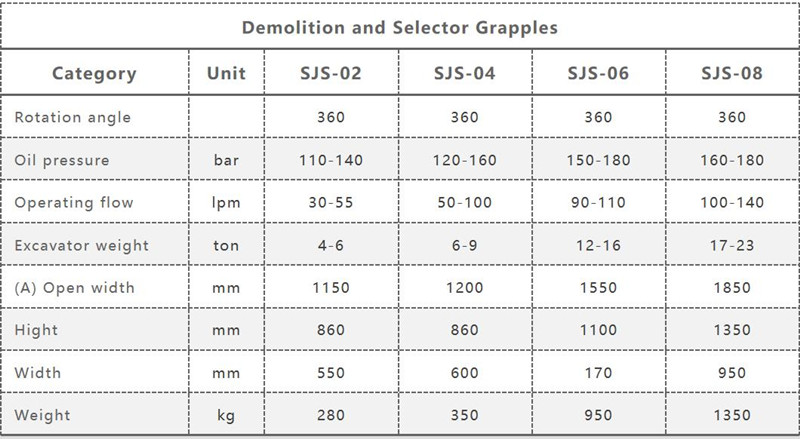

4. Do Demolition Grapples Have Sizes?

An excavator demolition grapple can come in various sizes and strengths, geared specifically to different budgets and projects. Lighter grapples are for lifting and moving materials, while the heavier and sturdier ones are for heavy-duty projects that involve demolition and land clearing.

Less elaborate grapples can still carry heavy loads, but their load capacity is minimal compared to the other types. This is because they usually have claw-like tines.

5. What Are The Different Parts/Attachments Of A Grapple?

Parts of Demolition Grapple

A grapple is composed of various parts and attachments. Here are the most important and notable ones you should know about:

- Lower Jaw– This is the lower half of the demolition grapple. It is usually pinned to the main pivot’s stick. Most cheaper models of grapples have an immobile lower jaw.

- Upper Jaw– The upper claw is the movable half of the demolition grapple that turns on the main pivot. It connects to the excavator’s power link.

- Tines– These are the multiple ‘fingers’ of the equipment. They are responsible for picking and holding up material. The lower claw has more tines than its upper counterpart.

- Tink Tips– These are the ends or “tips” of each tine. You can either prolong or replace these tips once they are worn out.

- Link Pin– This pin connects the upper claw of the demolition grapple to the excavator’s power link.

- Mounting Pad– The mounting pad is the welded bracket at the bottom of the excavator stick. It positions the lower claw correctly and helps it distribute stress evenly through the stick while in use.

6. How Much Is A Demolition Grapple?

The price of a demolition grapple depends on several factors. Among the main things that can affect the price range are brand, quality, and where you bought it.

You can find a demolition grapple at a starting price of $1,000. Expect this amount to increase as you consider higher quality ones. You will probably stumble upon options that reach over $20,000; these are higher-end brands and have the best quality.

Since a grapple is heavy equipment of considerable size, you should expect to spend a good amount of money if you want to purchase one.

7. What Are The Main Advantages Of Demolition Grapples?

Demolition Grapple Advantages

With the invention of the demolition grapple and selector grab, the scrap industry has slowly but surely reformed. Cleaning up scraps is not the only thing possible right now — you can also collect and recycle debris within a few hours! Here are a few more advantages you can expect by using demolition grapples:

- Versatile Sorting

After demolishing a large building, the builder would need to think about sorting and recycling next. Using a selector grab can help you handle both processes effortlessly. Not only can you grab large scrap items, but you can also move around the volumes of materials using these demolition grapples.

Demolition grapples are highly versatile equipment. You can use the iron jaws to move various materials around the construction site — may it be scraps, waste, wood logs, and even large pieces of blocks! These rugged claws will undoubtedly benefit almost all industrial sectors that need to maneuver large items.

- High Reach

You will need to reach high areas for construction and recycling duties. Some demolition grapples and selector grabs can extend to high places. They can move effortlessly along the walls and edges of containers and buildings.

- Saves Labor Time

It is not easy to handle and sort large wood logs, building scraps, and items. Large blocks of metal, cement, and steel will remain after demolition. Collecting them will take hours, eating up time you could have allotted for other, more productive duties.

Dealing with these yards of materials and scraps will require you to use a demolition grapple since it saves labor time. Some grapples have reinforced metal claws with ample surface space, allowing you to carry heavier objects simultaneously.

- Amazing Clamp Force

Sites dealing with demolition or construction are places full of danger. It is best to take extra care and precautions. Any loose clamps will lead to poor handling of scrap, which is incredibly dangerous. Most demolition grapples are mostly equipped with robust clamp force systems.

8. What Is A Demolition Grapple’s Weight Capacity?

Demolition Grapple Weight Capacity

A demolition grapple’s weight and load capacity will depend on the model and size. It can weigh anywhere from 300 lbs up to 1.5 tons.

That is the average, though. You might be able to find grapples that can carry more than 2 tons. Here is a video showing a demolition grapple carrying immense weight:

9. Can You Rent Demolition Grapples?

Hundreds of companies and businesses offer demolition equipment and attachments for rental. Amongst those are demolition grapples. You will have to find one near you for your own convenience.

10. What Are The Things To Consider When Looking For A Demolition Grapple?

Demolition grapples might focus on brute force, but that does not mean that every model is suitable for every application and use. Some grapples specialize in handling bulk material, while others can only carry smaller scraps.

Therefore, you should look at the features that differentiate and distinguish demolition grapples. Doing this helps you choose the right one that will fit your needs.

11. Grapple Capacity

Demolishing takes days, weeks, or even months to accomplish. It is not something that you can do overnight. You can, however, shorten this period by choosing a grapple with a hefty load capacity.

To capture the maximum amount of debris and scrap, ensure that your grapple capacity ranges from at least 0.5 yards to 1.56 yards.

- Job Size

Grapples rely on their interlocking tines to secure the materials in place to grab and hold material. A grapple has two sets of tines, with one side having one more than the other. Although, tine configuration will vary depending on the model.

The job type and material your demolition grapple can handle will depend on the number of tines that are appropriate for the work. As the size of debris increases, the number of tines should go down.

- Grapple Weight

The grapple’s weight is significant to your excavator. Grapples on the heavier side are best suited for holding heavier loads and materials. However, ensure that your excavator can handle the weight. You need to make sure that it is up for the job.

- Durability

Like fork tines, grapple tines can also bend. The chances of it happening is high if the grapple is poorly constructed. That would be an enormous waste, especially since grapples are expensive equipment.

When buying a grapple, make sure to purchase one with a wear-proof seal and hardened steel hinges. Look for one made from high-quality materials. It is far more expensive, but rest assured that it would not just buckle under pressure.

11. How To Maintain A Demolition Grapple?

Demolition grapples are easy enough to maintain. Make sure that you use factory service parts. Grease points are easy to reach for daily maintenance. Also, you would not have any trouble removing the maintenance panels.

Lubricate the machine daily. If necessary, make a lubrication schedule. Inspect every part with critical eyes every day.

Use an inspection checklist to ensure that you do not forget anything. It would help to have two people inspect the machine before use.

12. What Are The Potential Applications Of Demolition Grapples?

Demolition Grapple Uses/Applications

There are several applications for demolition grapples. The most obvious one is for demolition and construction sites, as well as scrap recycling sites.

You can use grapples on handling and placing concrete, large items, and blocks. It is also handy for dismantling, loading, and unloading jobs.

13. What Jaw Types Does A Demolition Grapple Have?

Demolition Grapple Jaw/Claw

Every grapple has its jaw design and type. Two jaws are attached to the frame of the excavator. The movement of the jaw will vary depending on the model.

In some models, the lower jaw remains stationary, and few versions have an immobile upper claw instead. There are also models with both jaws moving.

A popular jaw design is an open jaw. It is suited for dealing with waste, recyclable items, and scraps. The open jaw design offers better visibility during transport. It also helps you screen out the materials.

14. How Are Mechanical and Hydraulic Type Grapples Different?

Type of grapple

In general, there are two main types of grapple you should be aware of; mechanical and hydraulic type.

A mechanical grapple uses the bucket cylinder to do its operations. The simplest design for a mechanical grapple is a stiff arm attached to the excavator’s dipper arm. It can handle big jobs, from picking up debris to demolishing a building.

On the other hand, a hydraulic type gets all its energy from the excavator itself. It has a hydraulic circuit that is attached to the grapple jaws. It is best for jobs that need precision.

Watch this video to see the hydraulic grapple in action:

15. What Are The Requirements Of Grapples?

You need to determine what you need the grapple to do. If you want to choose the right grapple, you must first consider the job or project type.

Picking the right grapple ensures that you will use it on multiple future projects. Also, you would be able to save money and increase productivity.

16. What Should You Remember When Using Grapples?

You need training before operating a piece of heavy-duty equipment like demolition grapples. It is not something you can use without proper preparation and experience — that can lead to accidents and injury. Below are a few rules to keep in mind if you want a safe operation:

- Read and study the Operator’s Manual on the excavator. Learn about every control lever and its corresponding function.

- Know about the maximum weight capacity of the excavator and grapple.

- Ensure a safe distance between the machine’s cab and the suspended material.

- Always wear safety protective equipment, including a hard hat, safety glasses, gloves, steel toe shoes, and hearing protection.

- Lower the grapple to the ground when you are not using it.

17. What Should You Avoid When Using Grapples?

There are, of course, things you should avoid doing while operating a demolition grapple.

- Avoid overloading the machine.

- Do not use a damaged or poorly maintained grapple.

- Never leave your grapple suspended in the air.

- Avoid any collision. It could lead to dangerous results.

- Do not change, alter, or modify the attachment or equipment, especially if you are not knowledgeable about the machine’s physical, technical, and mechanical aspects.

- Do not attempt to repair the machine. Ask a professional for help.

18. How Do You Store A Demolition Grapple?

To store a demolition grapple, you need to place the attachment first on a solid and level surface. Apply grease to the pins, bores, and any other unpainted and exposed surfaces.

If you are worried about losing or misplacing the pins, you can remove them from the machine. Please place them in a proper storage place.

19. What Are The Safety Devices You Need While Using A Demolition Grapple?

At most, you will need to wear a seatbelt. Other safety devices you need are flags, warning lights, barricades, signs, visual or audible warning devices, shields, guards, safety decals, and canopies.

Having these devices around while the demolition grapple is running would be safer for everyone on site.

20. What Are Other Types Of Industrial Grapples?

Types of Industrial Grapples

Demolition grapple is not the only type of grapple you can use for heavy-duty work. Other grapples have their own application and use.

Log grapples are most appropriate for forestry-related projects. They can pick up full-length timbers and wood.

Orange peel grapples are primarily for material handling. They have a 360 rotation feature that is best for picking up loose scrap.

Narrow tine grapples can dig scrap easier. It also mainly handles soft debris.

Demolition Grapple Buying Guide – Tear The Buildings And Walls Down Like a Pro

What Is A Demolition Grapple, And What Is It Used For?

Demolition may seem fun and rewarding until you have to do it yourself! A demolition job requires the proper tools and equipment. When an old building is razed to make way for a new project or to level land, it’s a source of utmost satisfaction.

Seeing a building razed and torn into scrap might seem gratifying, but clearing the construction scrap requires extra care and effort. The serious works require rugged tools and equipment, and that’s where the demolition Grapples or Selector Grabs come in.

A sorting grapple does the same thing as “Iron Claw” and its application! Construction sites are commonly seen with this iron claw made from rugged material. As its name implies, the grapple grabs construction debris and scraps to clear the area. Hence, you can use these demolition grapples on excavators for everything from rebar to insulation.

You can use the sorting grapples to demolish an ancient building or a construction site with great ease! In addition to reducing labor time, these demolition grapples emit lower operating costs. Laborers can clear a site area in hours, but demolition grapples can do the job in minutes.

Furthermore, demolition grapples are not restricted to construction sites. They can also be extremely helpful at construction or renovation sites. The jaw can provide a high level of total load control, allowing the rapid sorting of scrap.

5 Features You’ll Love about Demolition Grapples

Demolition grapples have revolutionized the industrial sector, particularly scrap recycling and sorting. A variety of versatile features ensures a more accessible and quicker job with these grapples. The following are the features in detail:

1. 360° Rotation- Freedom of movement:

Construction sites are filled with obstacles and hurdles! A lack of flexibility and freedom of movement will make it difficult to perform tasks on the field. Sjheavy Demolition Grapples will ease your job with their 360° rotation. The grapple jaw can be moved in any direction, even in narrow places, without moving the entire machine.

2. Synchronized Jaws- Enhanced Control:

The control and movement of metal jaws do not have to be devised every time! Demolition grapples for excavators have a synchronized movement that is repeatable every time. So, you’ll be able to achieve the level of control and precision you’re looking for.

3. Smooth Inner Profile:

Scrap handling is one of the most challenging jobs in the world! The reason is that handling sharp metal objects, broken glass pieces, and heavy cement blocks is always dangerous. A synchronized jaw and a smooth interior profile provide a solution to the problem. Moreover, the smooth inner surface also led you to easy unloading without any hassle.

4. Wide Jaw Opening- Without Hassle Loading/unloading:

Because this “Iron Claw” can unload scraps and grab scraps at ease, it is called Sorting Grappler. With the “Wide Jaw Opening” feature, it can open up to 7 feet (2.2 meters) or more, depending on the brand and model, and lift larger objects without hassle.

5. Open Jaws- Handle with Ease:

There are many different types of grapples, each suitable for a different purpose. The open jaw design is considered the most suited design when dealing with scraps, waste, and recyclable items. Due to the open jaw design, you will have better visibility when moving around the site area and you will be able to screen out the material on your way. Those demolition grapples do a great job on the field when it comes to picking up, screening, and unloading!

Industry-Leading Features of Selector Grab – The Real Value

With the invention of selector grab for excavators, the scrap industry has been transformed! It is not only possible to clean up the scrap industry, but also recycling and garbage collection sites within a few hours. Sorting grapples are major service elements for handling scraps and other discarded materials.

Versatile Sorting:

While demolishing a building, what might a builder think about? I need to sort and recycle! By using the selector grapple, you will be able to handle both scraps. You can move around the volumes of material using these sorting grapples, but you can also grab and sort large scrap items.

The most important feature is the versatility of these grapples. You can use these iron claws to move different materials around the site, including wood logs, scraps, waste, and even large blocks. Consequently, these rugged claws on-field will benefit every industrial sector that needs to move large items.

You can consider these as a perfect tool to manage the following site areas.

- Primary and Secondary demolition site

- Construction site

- Scrap recycling site

- Building retaining walls

- Handling and placement of concrete, blocks, and large items

Saves the Labor Time:

It is not an easier task to handle the large wood logs, scrap items, and building scrap. Large blocks of cement, metal, and steel will remain at the demolition site, as well as broken glass. Consequently, dealing with the “hands” on-site will leave you with no productive results.

Thus, dealing with all those yards of scraps will require you to have the proper “Demolition Grapple” to save labor time. The Sjheavy demolition grapple has a reinforced metal jaw with a larger surface area (over 7 feet or more) to carry the heavier objects in no time.

High Clearance- Easy to Reach:

For recycling and construction duties, you will need to reach areas where high-profile grapples cannot. Therefore, it is necessary to buy the one which presents you with the “Zero Clearance” level. The grapples are most often equipped with this feature and can move easily along the edges and walls of the containers.

Amazing Clamping Force- Hold Firmly!

Sites where construction or demolition is taking place are full of danger, as we have already mentioned. In these situations, you need to take extra precautions and be concerned about security and safety. Therefore, any loose clamp will result in poor handling of the scarp, and this whole scenario can be dangerous. The Sjheavy demolition grapples are mostly equipped with a “High Clamping Force” system, which speeds up cycle times and increases overall productivity.

Key Components and Functionalities – Beyond Elegance

On a construction site and demolition site, demolition grapples will be in abundance. The features, including 360-degree rotation, fast sorting, precise load control, edge-to-edge contact, and zero clearance, will allow you to work seamlessly while moving around heavy objects on the field will be a breeze.

What are demolition grapples made of and how do they work? The following are some of the key components of sorting grapples and their functions. Let’s delve into more details!

| Components | Functionalities |

|---|---|

| High torque motor | No one would love to spend thousands of dollars on the same machine twice or thrice. Thus, a high torque motor ensures the prolonger life without any maintenance needed and induces a protected rotation. |

| Reinforced Jaws | No matter what your handling material or site is! Sjheavy demolition grapples can tackle everything from broken glass pieces to heavy cement stones with their reinforced jaws. |

| High-Grade Steel Components | The jaw and its peripherals are made up of high-grade and abrasion-resistant steel material to bear the impacts. |

| Overbite Stops | The Sjheavy demolition grapples are equipped with overbite stops to induce an edge-to-edge condition. This way, the demolition grapple for the excavator can even pick up smaller items with no hassle. |

| Cutting Edges | The cutting edges of this type of grapple are easily replaceable and hence increase the machine’s overall life. |

Buying Guide – Things to consider while buying the Demolition Grapples

Demolition grapples might have an element of brute force, but not every model is appropriate for every application. Some specialize in bulk material handling, while others handle a smaller amount of material. The most experienced workers shift the large cement blocks, while others shift only the scrap. That’s what the demolition grapples do!

Therefore, everyone should look for the features that distinguish demolition grapples and help them choose the right one for their needs.

Job Size:

The grapples, as we already know, have the tines, each piece having more than the other in order to grasp the scraps and other materials firmly. It depends on the model and varies for each job how the tines are configured. The universal rule implies, “The larger the object you are shifting, the fewer times you will need.”

Grapple Capacity:

Demolishing a house takes days, weeks, or months, and cannot be done overnight. To capture the maximum amount of scrap and debris, make sure the grapple capacity ranges from 0.5 cubic yards to 1.56 cubic yards.

Weight of Grapple:

Your excavator is dependent on the weight of the demolition grapple. It can weigh up to 300 pounds; a maximum of 1.5 tons. In the same way, the size of your job will determine the weight of your grapple. With a heavier grapple, you can handle heavier objects more easily and vice-versa.

Send Us A Message