Excavator Log Grapples – Sjheavy

We Deliver Excellence

Sjheavy excavator log grapple is a type of excavator grapple attachment primarily used for handling, moving, loading, and organizing wood, log, lumber, stone, rock, and other large debris.

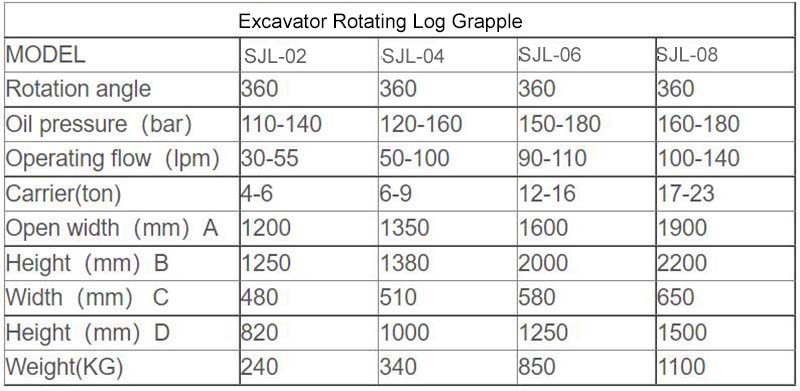

Sjheavy’s Excavator log grapple is available in a variety of sizes and models to accommodate projects of all sizes and types.

If you’re looking for a good excavator log grapple, Sjheavy is here to help you. Please send us a message to learn more about our products.

Incredible Clamping Force

Sjheavy timber grabs for excavators are perfect for timber handling. The load is securely held tight thanks to the excellent closing properties, whether clamping multiple logs or simply one.

Sjheavy excavator timber grab has a larger grapple, a more robust boom, and a hydraulic rotator. The sturdy mount allows for accurate load handling and positioning.

The structure’s solidity is ensured by the excellent quality of the materials and the specific reinforcements soldered on the forks.

Features and Functions

- Swing bearing system that rotates 360 degrees

- Tines that interlock for secure clamping

- Made of wear-resistant steel with a high tensile strength

- Large-capacity cylinders increase grasping force, allowing you to complete tasks in less time

- A double piston rod seals on a high-pressure cylinder

- Brake valve that provides protection against inactivity and accidents

- A heavy-duty chassis and the slew ring are big in diameter.

Orange Peel Grapple

With industry-leading technology, Sjheavy orange peel grapples are so tough and durable that the limits are being pushed. Because of their steel alloy bodies and abrasion-resistant tines, these orange peel grapples make your job easier than ever.

Demolition Grapple

You can use the Sjheavy sorting grapples to demolish an ancient building or a construction site with great ease. In addition to reducing labor time, these demolition grapples emit lower operating costs. Laborers can clear a site area in hours, but Sjheavy demolition grapples can do the job in minutes.

Excavator Rock Grab

The Sjheavy rock grab on the excavator can be used to shift large stones, rocks, and scrap. Due to its sharp tines and cutting edges on the front, the stone grab attachment can dig deep into the scrap in order to fully load the inner space of the grapple.

The Brand That Matters

Sjheavy is a one-stop solution provider that houses all forms of grapples at one location.

We are China’s leading excavator grab manufacturer, with ten years of expertise designing and producing excavator log grapple attachments.

Sjheavy’s service is responsive and offers personalized support to our distributors, resellers, contractors, and end-users. We also provide excellent after-sales support to assist you in properly maintaining your equipment.

Sjheavy offers exceptional items to its clients all over the world. To complete your order, we use an advanced ERP system. It will take 7-14 days for the product to arrive at your door.

The excavator log grapple from Sjheavy is highly adaptable. Send us a message if you’d like to learn more about our impressive product line.

Gallery

Why Sjheavy?

Sjheavy offers a complete line of log grabs for excavators weighing 3 to 40 tons. You can utilize Sjheavy excavator timber grab for various forestry tasks such as lifting, loading, and clearing.

Sjheavy log grapple for excavator hydraulic components is highly durable and requires low maintenance.

The mini excavator log grapple is made of heavy-duty material that will not deteriorate even after years of operation.

The best materials are used to build the Sjheavy excavator log grab. We work with reputable industrial suppliers to ensure that you get high-quality, long-lasting products at a reasonable price.

Before putting our items on the market, we ran a testing series. Every Excavator log grapple we make goes through a rigorous process overseen by a professional.

Sjheavy has several accreditations, including ISO 9001 and CE certifications. As a result, we can guarantee that you will receive the highest quality products.

FAQ for Excavator Log Grapple

FAQ for Excavator Log Grapple

Table of Content

FAQ for Excavator Log Grapple

An excavator log grapple is the most efficient tool to do the job when it comes to timber handling. It is easy to operate and can handle all log shapes and sizes. Check out some of the most frequently asked questions about excavator log grapple and know more about this amazing machine.

1. What Is An Excavator Log Grapple?

Excavator log grapple

An excavator log grapple is one of the many attachments available for excavators. It is particularly efficient for material transport, especially timber. This grab is designed to handle large tree trunks, and you can move them quickly on a lorry or dump truck.

You can also use this to carry debris and other materials to the construction or forestry site. It is an excellent attachment for mini excavators as well, as it comes in various sizes and load capacities.

2. How Much Is An Excavator Log Grapple?

Excavator log grapple price

The price of an excavator log grab differs depending on several factors, such as size, brand, and special features it may include. Usually, a brand-new excavator attachment cost ranges between $1,500 to $2,000.

You can also purchase used excavator log grabs at a lower price, as high-quality grapples can maintain their value even after years of service. You can find several listings on the internet, or you can ask a dealer from your area to give you the exact cost of the available attachment.

3. What Kind Of Jobs Can A Log Grapple Do?

Excavator log grapple jobs

Log grapples are versatile tools and can be used in various works. However, there are three main jobs this attachment is best at:

- Timber handling

Due to the ergonomic design of this attachment, with two hooks that clamp one another, it is excellent at grabbing logs. When it comes to handling large tree trunks, stumps, and branches, manual labor will only slow down the progress.

However, this grapple can easily lift wood chunks. Many logging companies use this attachment to manage their resources and provide a helping hand when it comes to loading and unloading timber trucks.

- Material transport

Log grapples are also frequently used in material transport since their convenience cuts down time and makes it easier to stockpile items. They can also put you into safety, as carrying heavy and sharp materials can become risky at times.

- Carrying discarded matter

Aside from forestry sites, you can also utilize excavator log grapples in construction sites. They can handle large rocks and debris well.

4. Can You Use A Log Grapple On A Mini Excavator?

Yes! There are log grabs for mini excavators. They may not be as heavy and big as the attachments for larger machines, but they are still durable and a dependable tool for all sorts of tasks.

Mini excavator log grapples can also come in different designs and features that may benefit the project you have in mind. You can always ask a dealer for the right size and design of log grapple for your mini excavator if you are unsure which one you need.

5. What Special Features Does A Great Log Grapple Usually Have?

Excavator log grapple features

Excavator log grapples are efficient on their own, but there are a few unique features that you might find beneficial for your project. Not all grapples have these, but it would be best to look out for the following features to ensure that you are getting the best:

- High-quality motor

An excavator log grapple rotating system and motor are usually the best ones among all excavator attachments. Most log grabs can rotate at 360 degrees, allowing them a seamless performance at stacking up piles of logs and other materials. It also makes it easier to reach anywhere without constantly moving the excavator itself.

- Premium quality steel

One thing that keeps a machine from wearing down quickly with constant usage and exposure to water is the steel they are made of. Low-quality steel is more likely to develop rust over time, which is not cost-efficient for a large machine.

Some of the best excavator log grapples in the market today are made of HARDOX steel. It is abrasion-resistant and durable, making it the perfect tool for forestry and construction. It also extends the life of a grapple, and you can expect to use it for at least ten years.

- Gripping teeth

There are a wide variety of gripping teeth available for excavator log grapples. Each is designed to use in different work environments and functions.

- Lightweight

You might associate heaviness with durability, but that is not always the case. It is possible to find lightweight grapples that are as sturdy and resilient.

They are also easier to operate and use less power. It does not add weight to the materials, so moving items from one place to another would be more convenient.

- Large capacity cylinder

When working with big projects, you would want a log grapple with a large capacity limit. It is more efficient to use and does the job in less time when compared to smaller capacity grapples.

6. What Are The Differences Between A Hydraulic And Mechanical Grapple?

Both mechanical and hydraulic log grapples are great tools for timber handling. However, they also have unique features that make them different from one another.

- Hydraulic grapples

Hydraulic grapples tend to be more expensive and require regular maintenance. However, it is a good choice if you want seamless manipulation in your operations.

They are also great for tasks that require speed and precision. They can get the job done at ease with minimal issues on the way.

- Mechanical grapples

Unlike hydraulic grapples, mechanical grapples are cheaper and require less maintenance upon service. However, they usually have a limited motion range, making it slightly harder to operate, especially for beginners.

Mechanical grapples are best to use in jobs that require less precision. They are still dependable, but it would not be the better choice if you want to finish the job immediately.

As mentioned, both log grapples are great tools, and it all depends on your preferences and project needs as to which of the two works best for you.

It will be worth it to invest in a hydraulic log grapple if you plan to use it for a long time. For short-term projects, mechanical log gabs would probably be the better option.

7. Why Should I Choose A Mechanical Log Grapple?

Mechanical timber grabs for excavators are best used in jobs requiring frequent material transport. Due to constant contact with abrasive materials, it would be best to choose low-maintenance equipment.

8. What Kind Of Tasks Require A Hydraulic Log Grapple?

Hydraulic log grapples are best to use in situations where there is a need for efficiency and precision. This includes stacking heavy materials on a dump truck, piling up large tree trunks, and other similar jobs.

9. How To Install A Hydraulic Log Grapple?

To install the log grapple to the excavator, you will first need to connect the attachment to the machine. Get the hydraulic lines to link, then lock them in place using pins.

Before trying them out, ensure that the attachment is properly connected to the excavator. Poorly installed attachments may lead to unwanted injuries and accidents.

10. What Components Does An Excavator Log Grapple Have?

The excavator log grapples three main components and understanding each of them will give you a better idea of how they operate.

- Body

An excavator log grapple body is usually made of solid and durable steel. This allows them to withstand heavy and abrasive materials over constant use. They can also come in a light-duty or heavy-duty body, and you need to keep that in mind before purchasing one for your project.

Light-duty steels are grade 30 and below, and their load capacity is usually at a lower cap. The good thing about them is that they require less energy to operate due to their lighter weight.

Heavy-duty steels are grade 50 and above, and they tend to be more resilient. They weigh more than the light-duty steels, but they also have a larger load capacity, which is instrumental in big projects.

Log grapples with heavy-duty steels are more useful in forestry handling more extensive materials.

- Arms

If there is one significant part a log grapple has, it would be its arms. This serves as the clamp of the attachment, allowing it to carry heavy loads of logs and debris.

- Reinforcement

Some excavator log grabs have a reinforcement rod that provides additional support to the tines or jaws of the grapple. It is often attached across the equipment and gives the grapple stability when lifting materials from one place to another.

11. What Makes A Good Excavator Log Grapple?

What is a good excavator log grapple?

Certain factors contribute to a good excavator log grapple, and this includes the following:

- Design

Design is an essential factor for a log grapple, as it determines which job you can use them for. Some grapples have arms or tines.

There are also degrees of rotation systems, sizes, shapes, and more. To know which one you need, you have to specify what kind of task you need it for.

- Quality

It’s easy to find cheap grapples in the market today, but you cannot expect them to come with high quality. Affordable tools are only good in the beginning, but they don’t hold their value over time.

On the other hand, high-quality grapples can last for at least a decade before you need to change them. This does not only save you money from buying a new one, but it also saves you money from maintenance and repair costs.

- Load capacity

A larger load capacity equates to efficiency. Of course, it all depends on their sizes, and you have to specify the capacity you need in order to find which brand and model best suits your project.

- Add-ons

These are only optional and considered a bonus from the basic needs, but having these can make your money’s worth. It includes hydraulic cylinder guards, hoses, couplers, and greasable hinge pins.

They are not always available for each product, but they are a great addition to the grapple.

12. What Are The Benefits Of Using Excavator Log Grapples?

Excavator log grapples are helpful in many ways, and there are ways of utilizing them in your business or ongoing project. It includes the following:

- Improved lead time

In a business, time is essential. You would want to make the most out of it in order to keep your company going.

With the help of excavator log grapples, loading and unloading materials can take less time when compared to if done manually. It also makes it faster for your clients to get their orders, giving you positive service feedback.

Aside from that, it can save you time and labor, and your employees will also thank you for that.

- Safety

At times, handling logs can be dangerous due to their heavyweight and sharp edges due to cutting. The employees exposed to timber handling are more susceptible to accidents and injuries, especially beginners.

Including this excavator attachment in your processes keeps your workplace safe for you and your employees.

- Efficiency

When it comes to business, there must be constant innovation and progression. Fortunately, you can have this with the help of log grapples.

Excavator log grabs make it easier to handle wood and even stack them at a clean pile when keeping them at bay. It would only take a few hours or even minutes to do one job, given that you have a high-quality tool attachment.

It also takes less effort to operate, so you and your employees don’t have to sacrifice your extra energy to make the most out of every day.

- Transportation

With the help of a log grab, it is easier to stack logs on a cleaner pile and make it easier to transport them from one place to another. Wood and large tree trunks are hard to manage when placed on trucks, but there is now a way to make that convenient.

It also takes a shorter time to do, and they can neatly organize the logs for you and the client’s liking.

- Mobility

As the log grapples are only an attachment, you can quickly bring them anywhere where you need them. Log transportation needs support from one place to another, and having this handy attachment makes the process easier.

The high mobility of log grapples makes it popular with most logging businesses and is considered one of the most sought-after tools. It is versatile and can easily handle all sorts of weather conditions, making it a reliable tool for timber and other materials handling.

13. Aside From Log Grapples, What Other Attachments Are Used In Forestry?

Other than construction, excavator grapples are also valuable for forestry sites. Some of these grapples include the following:

- Flat-bottom bucket

Flat-bottom buckets are known for their functionality. They are best used in disposal and clean-up, and they scrape the ground that can carry all the tree bits along the way. However, the size of the tree debris it can hold is limited at time.

- Bunching grapple

These grapples look closely similar to log grapples, but they have single cylinders and bypassing arms to scoop small logs in bunches. They are especially useful in unloading wood from roadside chipping and job site grinders.

- Grapple saw

Grapple saws are handy at tree-cutting sites. Its sawing feature allows crew members to finish the job with less risk because there is no need to have a man on the ground cutting the trees.

After cutting, they can also immediately deposit the wood where it is supposed to go.

Send Us A Message