An Excavator Breaker Exactly Meet Your Requests – Sjheavy

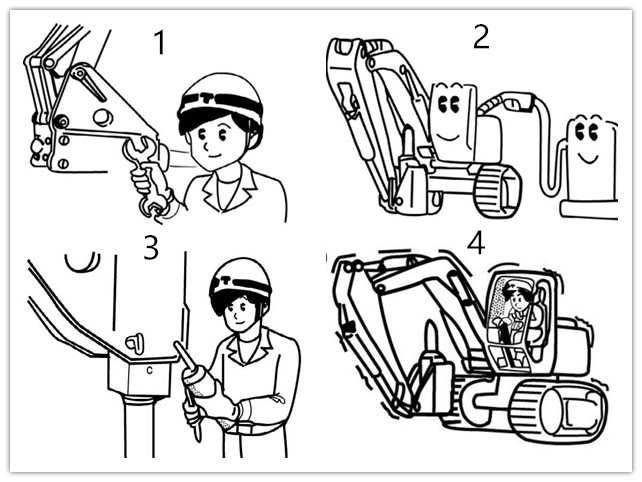

Match Your Excavator 100%

The Sjheavy DM series excavator breakers are born for mid-size carriers. It wins for simple structure design, low maintenance cost, and stable working performance. There are so many excavator breaker brands in the market. People may get a headache about what models to choose from. Like when picking a 20-ton class excavator breaker, you may have questions like:

Shall I buy a box or top type bracket? Does the hammer need an accumulator or not? Is a Soosan or Furukawa hammer better fitting my excavator?

Well, we can solve all your concerns. The Sjheavy excavator breaker is right there exactly matching your carrier. It can perfectly handle your working applications and take full advantage of your budget. Get a quick quote now!

Box or Top Type Bracket

Choosing the best bracket type may be an issue for you. A dealer may not tell you those details but they are truly important that can save you big money.

The top type excavator breaker is recommended in hot regions like the Middle East, North Africa, and Central America. Considering the scorching climate and harsh environment there, a top type excavator breaker has better cooling performance and easy to maintenance. The heat-resistance Seal kits are also required for cooling demand. They can keep the hammer in smooth working condition.

The box-type bracket, also known as silence type, full-housing type, is the most popular design now. It is highly recognized in Europe, Australia, and North America. It is popular because of better protection to the main body and noiseless working conditions.

Besides, there is also a side type bracket. It is mostly used in China, Vietnam, and some surrounding countries. Compared with the top or box type bracket, it has better operating vision because of lower arm height during working.

The Sjheavy DM series excavator breaker has all the 3 above bracket types available. We also offer bracket types particularly designed for skid steers and backhoes. Leave a message to us if you are not sure about that.

Accumulator or Not

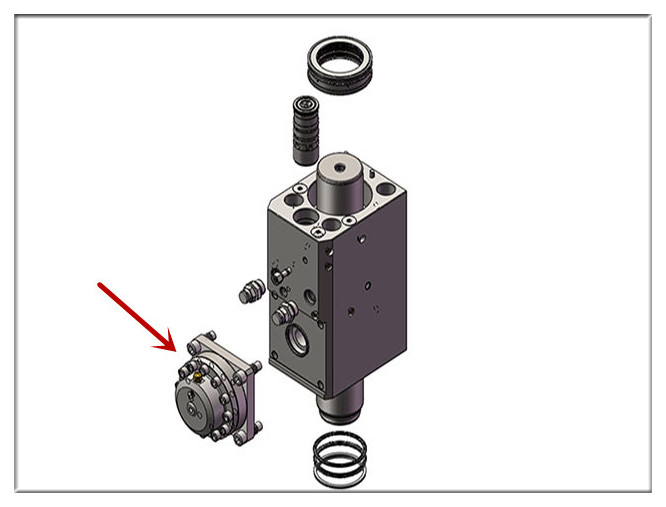

What is an accumulator?

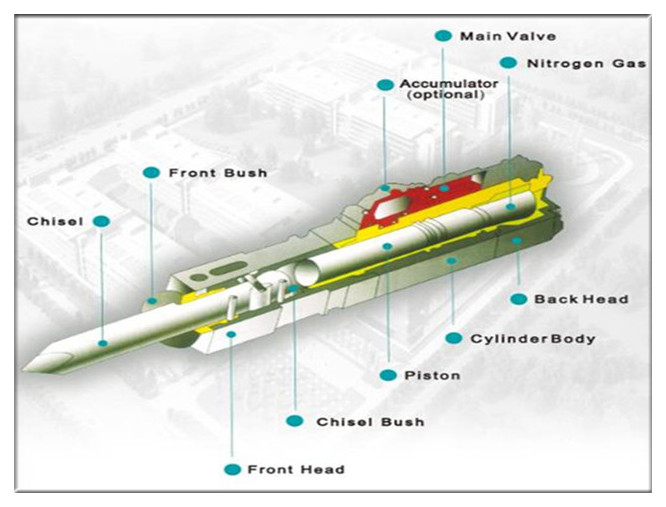

The accumulator is a component installed on the excavator breaker cylinder. It is filled with nitrogen. When the piston strikes, The accumulator stores the energy of the piston’s recoil and releases the energy during the next strike. It is originally designed to increase striking ability.

Does the excavator breaker need an accumulator?

The accumulator is widely used in early Furukawa designs. The Frd20G, Frd30G are the most popular models in the early years. Many people still love them today. But the current trend is towards non-accumulator design. Actually, even the new Furukawa design also cancel it. Brands in Europe, America, China, Korea, and Japan are all canceling the accumulator, and they do it for some reasons.

- Today’s hydraulic technology enables the breaker to generate sufficient striking force without the need for an accumulator.

- The diaphragm inside the accumulator may get damaged when nitrogen is not enough. It will lead to a weak blow of the hammer. A replacement will cost hundreds of dollars.

- Canceling the accumulator can reduce body weight and save maintenance costs.

- The non-accumulator design is a more simple structure with a lower failure rate.

In conclusion: The accumulator is an old-style design that is no longer necessary for today’s excavator breaker. They still work out for some heavy-duty models, but not a must for the mid-size any more.

FURUKAWA or SOOSAN

The Furukawa and Soosan excavator breakers are quite popular in the retail market. HB20G and SB81 are some of the best sellers. The Sjheavy DM series breaker is a particular series combining the good features of both. No matter what series of breakers you like, we satisfy you 100%.

What is the difference?

Well, we may be the only one in the industry that can explain the thing up specifically.

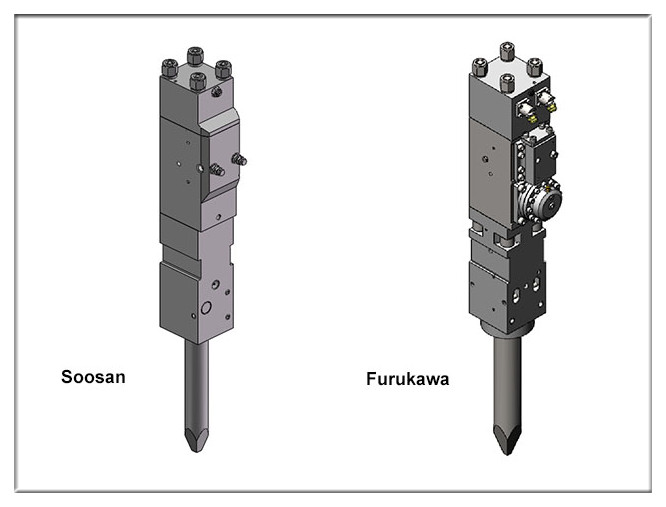

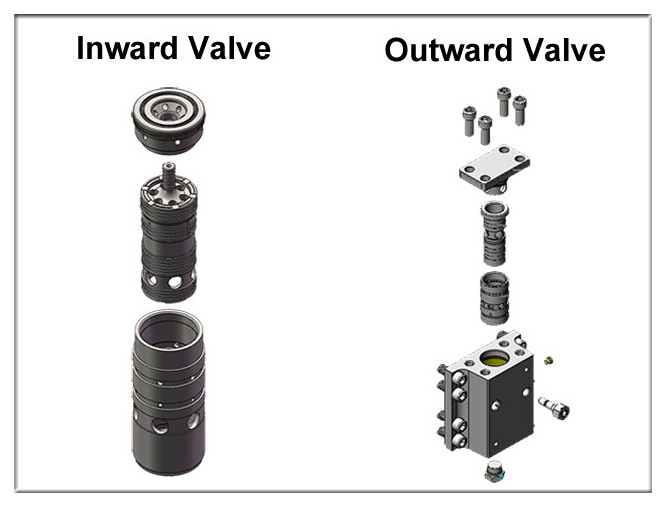

Check the picture above. Everyone can see the main differences between both refer to the cylinder assay.

- The Soosan has a control valve installed inside the cylinder, while the Furukawa has an outward valve.

- The Soosan mid-size series does not have an accumulator, while the Furukawa does.

Obviously, the Soosan has fewer components needed and is simpler in structure than the Furukawa.

Which design is better?

Well, it is tricky to define a better one. But technically, I can explain to you the benefits of both ones so you can make your own mind. To makes things down to the earth, I take SB81 and HB20G for comparison. They are both available in the Sjheavy DM series brochure(DM1400 and DM1350).

The SB81(DM1400) excavator breaker has a simpler structure and is easy to maintenance. It can save you money in the long run. With a 140mm diameter chisel, it has better striking force with higher productivity. If you are working on a quarry, breaking granite or reinforced concrete, the SB81(DM1400) can handle your job more efficiently. It is one of the most popular designs for a 20-ton class, selling in the USA, Europe, Australia, India, China, etc.

The HB20G(DM1350) is an old design from Japan. The biggest advantage is stability. The outward valve has better cooling performance and the accumulator makes less pressure on the excavator’s arm. These features make it work better in hot environments, particularly in the Middle East, North Africa, Latin America, etc. With a 135mm diameter chisel, it has a faster hitting frequency compared with SB81(DM1400). If you are driving a 20-ton excavator for road building or concrete demolition, it is a good option.

Contact us for a free quote, or let us help you decide the best match for you. We know your requests more than others do.

Advantage Features of DM series Excavator Breakers

Casting Forged Cylinder: Qualified alloy steel SCM440, SCM420 makes the best body.

Long Stroke Piston: The specialized designed piston maximizes impact.

Speed Control: A cylinder valve adjuster controls hitting speed and strike force.

Tripple seals: Dust seals, step seals, and back-up seals ensure no oil-leakage.

Different Match: replaceable bracket bushes match different excavator models.

Powerful Impact: hydraulic and N2 gas power hits hard.

Reinforced Front Head: Stronger pins and advanced bush design keep it robust.

Reliable Bracket Design: New reinforced bracket avoids cracking and bolt damage.

FAQs

Q: Is your breaker body solid enough?

A: Qualified materials, advanced process and heat treatment, standard hardness check. Each batch is of the same performance.

Q: How to adjust the excavator breaker according to different applications?

A: Tighten or lose the valve adjuster(1.5 cycles) to control hitting speed. Adopt fast impact mode for breaking concrete, and slow mode to handle the rock.

Q: Does the Sjheavy DM series breaker have an accumulator?

A: The trend today is of non-accumulator design. It balances performance and reliability. But we still keep model DM1350 available for accumulator-type lovers.

Q: How to keep it working smoothly?

A: It is very easy to maintenance. Just grease it every 2 working hours, replace the seal kits 3-6 months, and let it work.

Get the Right Excavator Breaker Model

In the mid-size excavator breaker range, many users are concerned about choosing the right model. There are many brands of excavator breakers on the market, the more well-known ones are Soosan, Atlas Copco, Furukawa, etc. Each brand of the breaker has its own naming rules, and users who buy for the first time may be confused.

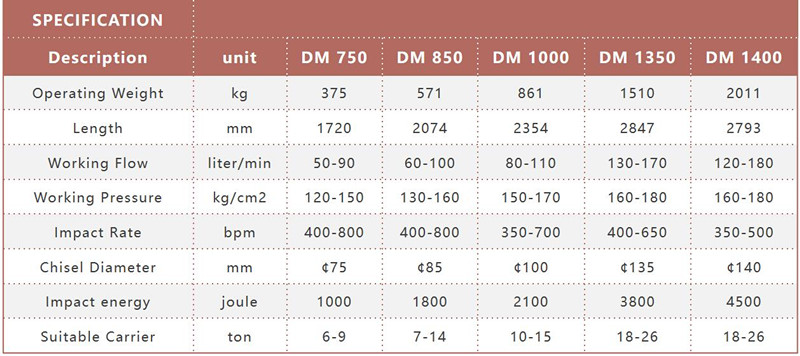

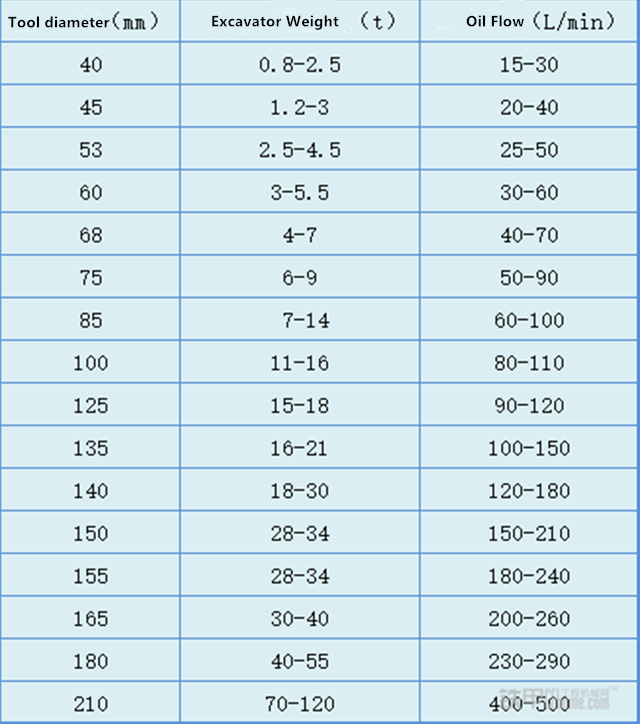

Take the Sjheavy DM excavator breaker, for instance, It is classified according to the chisel diameter. The “DM1000” refers to the hammer with a chisel diameter of 100mm, and the “DM140 ” refers to the chisel diameter of 140mm breaker.

Common breaker chisel diameters are 40, 45, 53, 68, 75, 100, 120, 135, 140, 150, 165, 175(mm), etc. There are many models between different brands. Let’s take a look below. See how big excavators these types of breakers should match.

Everyone should understand when you see this table. The question that many people have had about “Can a 6-ton small digger be installed with 68 hammers” is answered here. The chisel diameter of 68mm may be installed at 4-7 tons on the excavator.

Of course, this is just a reference value. A more accurate matching method is to check the pressure and flow required for the normal operation of the breaker, and compare it with the pressure and flow of the hydraulic system of the excavator. If they match, then you can rest assured to install and use it.

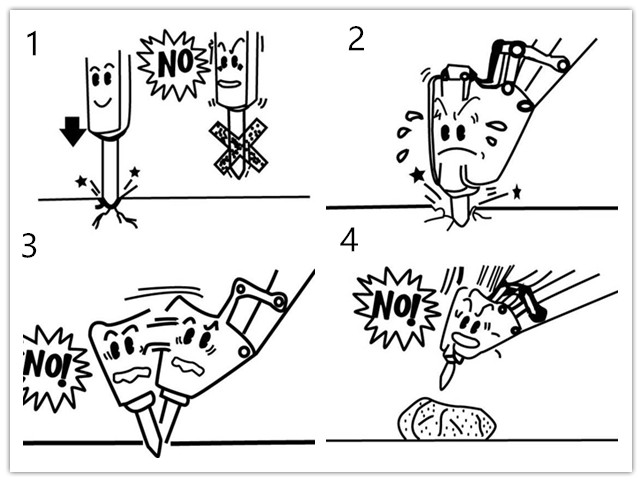

The harm of unreasonable matching of breaker and excavator

There is a word in the industry called “small horse-drawn cart”, this sentence is more used to describe the excavator matching an engine with too small power, in fact, this statement is also applicable to the breaker.

The matching breaker is too large

This is really a “small horse-drawn cart”, and the flow and pressure of the hydraulic system of the excavator cannot meet the requirements of the breaker for normal work. In this case, if the operation is forcibly carried out, it will seriously damage the engine and hydraulic system. At the same time, the frequency of the hammer will be reduced or even cannot be hit normally, affecting the efficiency of the crushing operation.

Matching with too small breaker

In this case, there is no harm to the excavator, but the efficiency of the operation of the breaker model is too small, which is not cost-effective in terms of benefit, and there is some damage to the breaker, so it is still recommended Everyone matches the breaker in a suitable range.

Contact us for more tips.

Before Use

Gas Charging and Adjustment

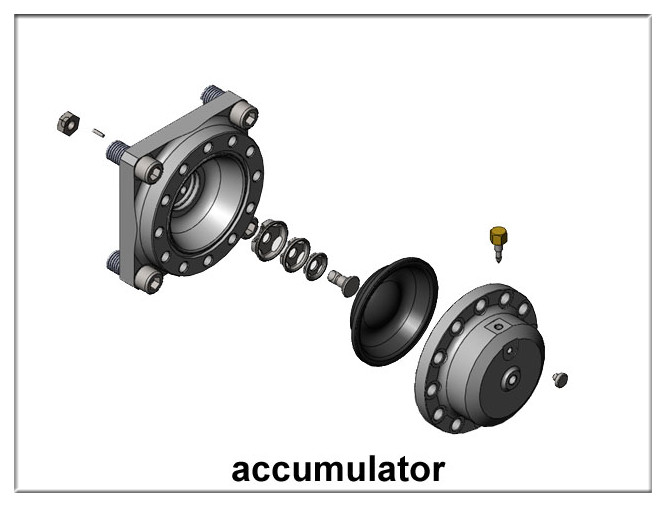

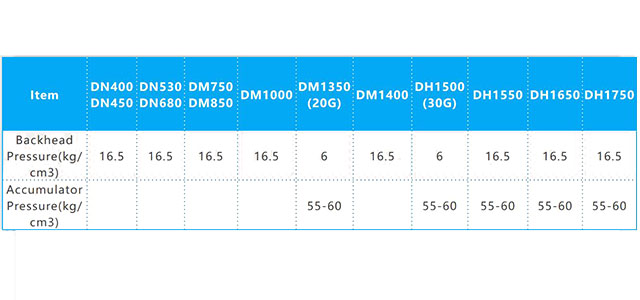

Please note: The nitrogen gas in the back head(nitrogen chamber) and the accumulator are normally filled to a certain number when installed in the workshop, and the nitrogen bottle going with the excavator breaker is empty considering shipping delivery.

The method of checking the gas pressure

- Take off the plug counter-clockwise, tighten the three-way valve clockwise, tighten the nitrogen gauge nut, and close the relief valve.

- Press down the switch on the three-way valve with your hand and read the nitrogen meter.

- If the nitrogen is excessive, release the nitrogen from the overflow valve of the three-way valve to make the nitrogen be standard.

The method of charging the gas nitrogen

- Repeat the method of checking the gas pressure 1 and 2.

- If the nitrogen is less, connect the high-pressure hose of nitrogen to the high-pressure hose interface of the nitrogen meter and the interface of the nitrogen bottle.

- Press the switch of the three-way valve down, turn on the switch of the nitrogen bottle slowly counterclockwise until the pressure of the nitrogen gauge to be n

- Three times of charging and three times of release to ensure the purity of nitrogen.

Set the pressure range of the Nitrogen chamber, accumulator

Form

Warning

- Do not remove the accumulator cover before the accumulator is deflated.

- Only use pure nitrogen, other air could cause the breaker to work unusual.

- The charging pressure: 55-60 bar.

- The gas pressure should be checked once a week, contact the dealer if necessary.

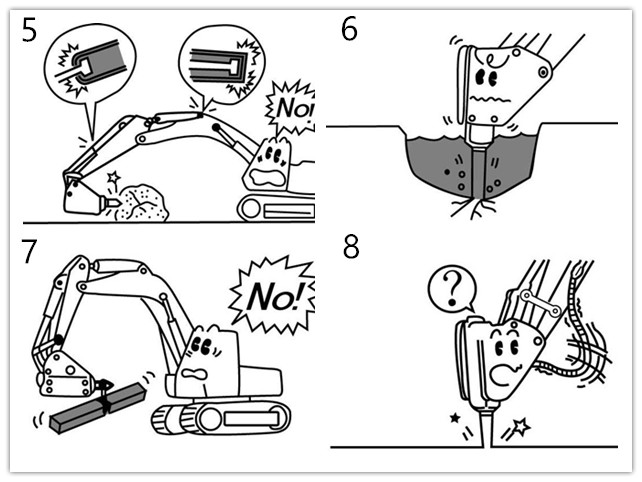

Dos and Don’ts

Dos

- Inspection of bolts and nuts: Please check whether the bolts and nuts of each part are loose.If it is, please tighten it immediately.

- Confirmation of hydraulic oil: Please confirm whether there is enough hydraulic oil. If the quality of hydraulic oil significantly deteriorates, please replace it immediately.

- Grease: Grease into the front head of the excavator breaker.

- Running in: The new excavator needs to run in for the first time 1 hour, running in 10 at the beginning of each day minutes, at 70% of normal flow when running in Left and right. The excavator breaker must hit vertically instead of striking diagonally. Avoid running at full capacity as soon as it starts, or the seals and other important parts will be damaged.

Don’ts

- No blank-firing: When the tool does not touch the broken object, the striking action is called “blank-firing”. It will cause damage to parts like bolts, nuts, etc.

- No striking continuously: Try not to strike continuously in the same place. This will cause abnormal wear of the tool and other abnormal damage to parts. If it can’t be broken after 1 minute of hitting, please change The location of the hit point.

- Do not shake the drill rod back and forth: It will cause the cylinder through bolts, drill rods, and retainer bushings to break and wearing.

- Don’t hit the object suddenly: The hydraulic excavator breaker is heavier than the bucket. You must operate the excavator slowly, and don’t violently hit the object. Otherwise, it will cause damage to the front and rotating parts of the excavator.

- Do not hit when cylinder at the end of the stroke: Do not hit the cylinder at the end of the stroke, please keep a margin of more than 100mm. Otherwise, it will cause damage to the cylinder and the front head.

- Do not use in water: Do not put the excavator breaker directly in the water for operation, otherwise, it will cause damage to itself.

- Don’t use it for hanging objects: Do not tie steel ropes to the excavator breaker, shell, or tool to lift and carry objects, otherwise, it will cause damage to the breaker body and the forearm of the excavator.

- When the hydraulic hose vibrates abnormally: If the hydraulic hose jumps abnormally, it means that there is gas leakage in the accumulator or nitrogen chamber. In this case, the nitrogen pressure should be checked and injected.

Project Gallery