Internal valve vs external valve structure

There are two main types of hydraulic breaker designs on the market: internal valve and external valve.

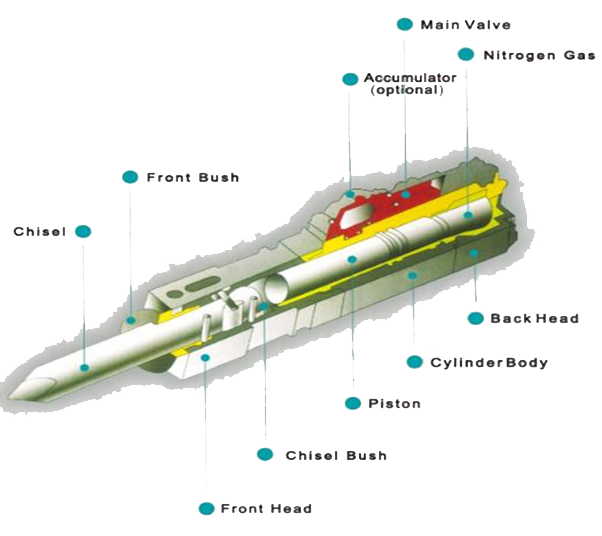

Internal valve

The design is simple and smart, with only two moving parts and fewer components.

The control valve is installed inside the cylinder.

The biggest advantage of an internal valve is düşük arıza oranı, kolay bakım, and low cost.

Most small and medium-sized breakers are internal types.

External valve

There are also excavator hammers that adopt an external valve design, Furukawa being a typical example.

These types of breakers are more complex in structure, with more components that cost more to repair.

But they also have their upsides.

The external valve provides more buffer to the hydraulic pressure, which cools down the oil flow and relieves the impact to the excavator.

All these factors are crucial to heavy–duty excavator hammers.

With an accumulator set up to further relieve oil pressure, both the hammer and the excavator are better protected from the high oil pressure.

That’s why most heavy-duty excavator hammers (over 50 tons) are external valve types.

Conclusion

Internal valve types have better performance for small and medium-sized breakers,

while external valves are better for heavy-duty excavator hammers.

So if you are interested in buying a small or medium size hydraulic hammer,

Or if you want to find a rock breaker that is easy to maintain and has reliable performance,

then the DEHN rock breaker is the right choice for you.

For more information about hydraulic breaker structure, visit this guide.